Concrete is a versatile and popular building material known for its strength and durability. When it comes to reinforcing concrete, rebar is commonly used due to its excellent tensile strength. However, many people have wondered if galvanized wire can also be used in place of rebar. In this blog post, we will dive deep into the topic and find out if galvanized wire is a suitable alternative for reinforcing concrete.

With the year 2023 upon us, it’s essential to stay up to date with the latest construction trends and techniques. Whether you’re a DIY enthusiast or a professional contractor, understanding the compatibility of different materials with concrete is crucial. So, if you’ve been contemplating using galvanized wire in your concrete projects, keep reading as we unveil the answers you’ve been looking for.

In this comprehensive guide, we will discuss various aspects related to the use of galvanized wire in concrete. We’ll explore its compatibility with different types of wires, the corrosion factor, and its effectiveness as a reinforcement material. So, let’s get started and uncover the truth about galvanized wire and its role in concrete construction.

Can You Use Galvanized Wire in Concrete?

Galvanized wire is known for its durability and resistance to rust, making it a popular choice for various applications. But when it comes to using galvanized wire in concrete, there are some factors to consider. Let’s dive into whether galvanized wire can be used in concrete and what potential issues may arise.

Understanding Galvanized Wire

Galvanized wire is steel wire that has been coated with a layer of zinc to protect it from corrosion. This coating adds a layer of strength and makes the wire more resistant to rust and weathering. It’s commonly used in construction, fences, and even artwork.

The Benefits of Using Galvanized Wire in Concrete

Using galvanized wire in concrete can have a few advantages. Firstly, the zinc coating provides an extra layer of protection against corrosion, which can extend the lifespan of the wire. Additionally, galvanized wire is generally stronger and more durable than plain steel wire, making it less prone to breakage.

Factors to Consider

While galvanized wire can offer some benefits, there are a few factors to consider before using it in concrete. One important aspect is the thickness of the galvanized coating. If the coating is too thick, it can prevent the wire from properly bonding with the concrete, compromising its overall strength.

Potential Issues

Using galvanized wire in concrete can cause some potential issues. As the concrete cures, it releases moisture, and that moisture can react with the zinc coating, leading to premature corrosion. This can weaken the wire over time and reduce its effectiveness as a reinforcement material.

Best Practices

To ensure the best results when using galvanized wire in concrete, it’s essential to follow some best practices. Firstly, consider using wire with a thinner zinc coating, as it can improve the bond between the wire and concrete. Additionally, applying an epoxy coating to the galvanized wire before embedding it in the concrete can provide an extra layer of protection against corrosion.

While galvanized wire can be used in concrete, it’s crucial to consider the potential issues that may arise. Understanding the benefits and limitations of galvanized wire helps in making an informed decision. By following the best practices and ensuring proper coating thickness, you can utilize galvanized wire effectively in concrete projects, providing durability and strength for years to come.

FAQ: Can you use galvanized wire in concrete?

Concrete is a versatile construction material used for a wide range of projects, from small backyard patios to large-scale infrastructure. When it comes to reinforcing concrete, there are different options available, including using galvanized wire. In this FAQ-style subsection, we’ll address common questions and concerns about using galvanized wire in concrete.

What metal is suitable for use with concrete

Not all metals are compatible with concrete. Some metals, such as untreated steel, can react with the alkaline environment of concrete, leading to corrosion and potential structural issues. However, galvanized steel, which is coated with a layer of zinc, is a suitable choice for use with concrete. The zinc coating acts as a protective barrier, preventing the steel from coming into direct contact with the concrete.

Should I use rebar or wire in concrete

The choice between rebar and wire for reinforcing concrete depends on the specific project requirements. Rebar, short for reinforcement bar, is a steel bar commonly used to add strength to concrete structures. It provides excellent load-bearing capacity and is often used in large-scale constructions.

On the other hand, wire mesh, which can be made of galvanized steel, is more suitable for smaller projects or for reinforcing thinner concrete slabs. It helps distribute the load across the concrete surface and reduces the risk of cracking.

Can you use fence wire in concrete

While fence wire may seem like a convenient choice, it may not be suitable for use in concrete. Fence wire is typically not designed to withstand the alkaline environment of concrete or provide the necessary structural support. It is best to use specifically designed wire mesh or rebar for concrete reinforcement.

Can you put Romex in concrete

Romex, also known as non-metallic sheathed cable, should not be directly embedded in concrete. Romex is intended for electrical wiring applications and is not designed to withstand the harsh conditions and moisture exposure that can occur within concrete. It is essential to follow proper electrical wiring practices and codes when installing electrical components in and around concrete structures.

How long will galvanized pipe last in concrete

The lifespan of galvanized pipe in concrete can vary depending on various factors, including the thickness of the galvanized coating, the surrounding environment, and the quality of the installation. However, under normal conditions, galvanized pipe can last for decades in concrete without significant corrosion issues. Proper maintenance and regular inspection can help prolong its lifespan.

Can steel be in contact with concrete

Steel can be in contact with concrete, but it is crucial to consider the potential for corrosion. Untreated steel in direct contact with concrete can react with the alkaline environment, leading to rust and structural problems over time. However, using galvanized steel, which has a protective zinc coating, can prevent this corrosion and ensure a more durable and long-lasting concrete reinforcement.

Does cement corrode galvanized steel

No, cement does not corrode galvanized steel. The alkaline nature of cement can actually help protect the galvanized coating by passivating it, preventing the zinc from corroding. This is one of the reasons why galvanized steel is a suitable choice for reinforcing concrete.

What type of wire is used for concrete

When it comes to wire reinforcement in concrete, steel wire mesh or rebar are commonly used. Steel wire mesh, often made of galvanized steel, consists of interconnected wires that help distribute the load and increase the tensile strength of the concrete. Rebar, on the other hand, is a steel bar that provides additional strength, particularly for larger-scale projects.

Does a 10×10 concrete slab need rebar

While the use of rebar in a 10×10 concrete slab may not be mandatory in all cases, it is generally recommended to reinforce concrete slabs of this size. The presence of rebar helps to minimize the risk of cracking and improve overall structural integrity. However, the specifics of each project should be evaluated to determine the appropriate reinforcement requirements.

Can you put electrical wire in concrete

Electrical wire should not be directly embedded in concrete. It is essential to follow proper electrical wiring practices and codes, which often require the use of conduit or other protective measures to ensure the safety and longevity of electrical installations. Consulting with a licensed electrician is crucial for determining the appropriate wiring methods for your specific project.

Does galvanized metal react with concrete

Galvanized metal does not react with concrete. The zinc coating on galvanized metal acts as a protective barrier, preventing direct contact between the metal and the alkaline environment of the concrete. This protective layer helps to inhibit corrosion and extend the lifespan of the galvanized metal when used in concrete applications.

Can you bury wire in concrete

While it may be possible to bury certain types of wires in concrete, it is generally not recommended for electrical wiring applications. Proper electrical codes and regulations require specific methods for burying electrical wires, which typically involve the use of conduit to protect the wires from moisture and potential damage. It is essential to consult with a licensed electrician to ensure compliance with safety standards.

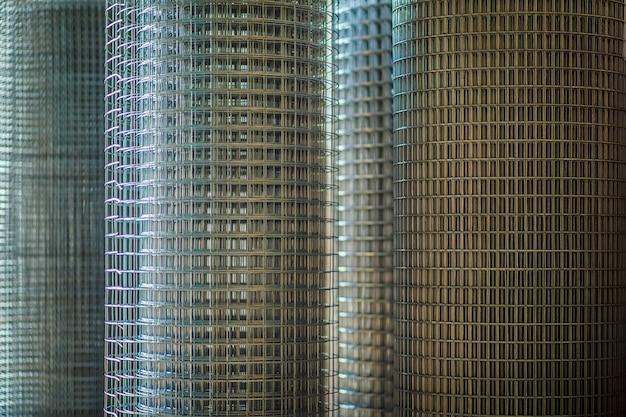

Can you use galvanized wire mesh in concrete

Yes, galvanized wire mesh is a commonly used material for reinforcing concrete. The interconnected wires of the mesh act as a support system, distributing load across the concrete and reducing the risk of cracks and failures. The galvanized coating provides protection against corrosion, enhancing the longevity and durability of the concrete structure.

What is the best material to reinforce concrete with

There are various materials available for reinforcing concrete, including rebar, wire mesh, and fibers. The choice of material depends on factors such as project requirements, load-bearing capacity, and budget. Rebar is often used for larger-scale projects requiring high tensile strength, while wire mesh is suitable for smaller-scale applications. Additionally, fibers, such as synthetic or steel fibers, can also be added to concrete to enhance its strength and durability.

Why is rebar not galvanized

Rebar is not typically galvanized due to the nature of its intended use. Rebar is commonly embedded inside concrete, and galvanizing it would require scraping off the zinc coating at connection points, potentially compromising its corrosion resistance. Instead, other methods, such as epoxy coating or epoxy-coated rebar, are often used to provide corrosion protection for rebar when needed.

Why is rebar green

Rebar is often coated with a green epoxy material, known as epoxy-coated rebar, for added corrosion resistance. The green color is simply a visual indicator that the rebar is coated with this protective epoxy layer. The coating helps prevent the rebar from coming into direct contact with the alkaline environment of concrete, reducing the risk of corrosion and ensuring the longevity of the reinforcement.

Can you use fencing as rebar

Using fencing as a substitute for rebar is generally not recommended. While both fencing and rebar are made from steel, they are designed for different purposes. Fencing wire is typically thinner and less strong than rebar, making it unsuitable for structural reinforcement in concrete. It is always best to use materials specifically designed for concrete reinforcement to ensure the safety and stability of the structure.

Should you use wire mesh in a concrete slab

Wire mesh can be beneficial for reinforcing a concrete slab, particularly when dealing with thinner or smaller-scale slabs. The interconnected wires of the mesh help distribute the load and reduce the risk of cracking. However, it is essential to evaluate the specific project requirements and consult with professionals to determine the appropriate reinforcement methods for your concrete slab.

How can I make concrete stronger without rebar

While rebar is a commonly used method for strengthening concrete, there are alternative approaches to enhance its strength. One option is to use fiber reinforcement, such as steel or synthetic fibers, which can improve the tensile strength and reduce cracking. Another approach is to employ post-tensioning, where steel cables or rods are tensioned after the concrete has cured, adding strength and stability. Consulting with a structural engineer can provide valuable insights and guidance on reinforcing concrete without relying solely on rebar.

What can I use instead of rebar

If rebar is not readily available or suitable for your project, there are alternative materials that can be used for reinforcing concrete. Wire mesh, as mentioned earlier, is a common substitute for rebar, particularly in smaller-scale applications or thinner slabs. Additionally, fiber reinforcement, such as steel or synthetic fibers, can also be used to enhance the strength and durability of the concrete.

What does the H stand for in rebar

The “H” in rebar denotes the grade of the steel used. Rebar can have various grades, each indicating the tensile strength of the steel. The higher the grade number, the stronger the rebar. For example, Grade 40 rebar has a tensile strength of 40,000 pounds per square inch (psi), while Grade 60 rebar has a tensile strength of 60,000 psi. The grade of rebar chosen depends on the specific structural requirements of the project.

Is it better to use rebar or wire mesh

The decision to use rebar or wire mesh depends on the specific project requirements. Rebar provides greater load-bearing capacity and is often used in larger-scale projects where high tensile strength is necessary. Wire mesh is more suitable for smaller-scale applications or thinner concrete slabs, where the primary goal is to prevent cracking and distribute the load. It is best to consult with professionals to determine the most appropriate reinforcement method for your project.

Is all rebar galvanized

Not all rebar is galvanized. Galvanized rebar is coated with a layer of zinc, providing additional corrosion resistance. However, galvanizing rebar is not done universally, and in many cases, regular uncoated rebar is used. The choice between galvanized and uncoated rebar depends on factors such as project requirements, environmental conditions, and cost considerations. It is important to evaluate the specific needs of the project before deciding on the type of rebar to use.

Remember, when reinforcing concrete, it’s crucial to consider the specific needs of your project and consult with professionals to ensure the proper choice and installation of reinforcement materials. By using galvanized wire, wire mesh, or rebar, you can enhance the strength and durability of your concrete structures, ensuring they stand the test of time.